During fluid activity, after subtracting the resistance loss of the steam pressure reducing valve group, the static and dynamic pressures convert to each other, but this is not a constant. The residual pressure outside the fan is the total pressure value after the fan overcomes its own resistance loss, that is, the total pressure difference between the inlet and outlet. The outlet wind speed of the fan is relatively high, the dynamic pressure is also relatively high, and the static pressure is relatively low. Therefore, generally speaking, the pressure head of the electric fan is full pressure, which can be said to reflect the function of the electric fan. The dynamic pressure and static pressure of wind are relative conditions. Dynamic pressure is actually the energy generated by the microscopic activity of a fluid. Therefore, in the absence of microscopic fluid activity, the steam pressure reducing valve will not undergo dynamic pressure. Static pressure is the internal energy formed by the thermal motion of the molecules of the fluid itself. Regardless of whether the fluid is in micro motion or stopped, its molecules continue to undergo thermal motion, which only determines the existence of hydrostatic energy, and has no relationship with micro activity.

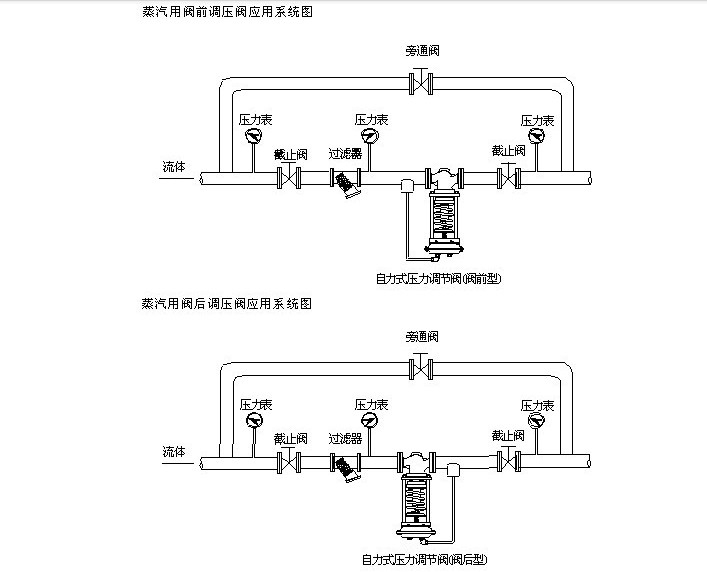

Generally used steam pressure reducing valves are divided into barrier type, tension spring type, and piston type according to the type of wet alarm valve, and are divided into proportional type and constant pressure type according to the type of action. The constant pressure type is equipped with a pressure regulating valve, which can simultaneously reduce the dynamic pressure and static pressure. The pressure in front of the valve can be freely changed, and the pressure behind the valve can be stabilized to the desired pressure. For large pressure reductions above 5:1, two pressure reducing valves should be used in series to reduce the pressure. When the flow rate changes greatly, double valves in parallel should be selected. For pressure reducing valve groups used in parallel, it is necessary to select pressure reducing valve groups with different diameters, and correctly set different rear valve pressures. Steam pressure reducing valves require two pressure reducing valves to be used in series to reduce pressure to achieve greater pressure reduction, such as greater than 5:1. In situations where the flow rate changes greatly, it is necessary to select dual valves in parallel, and use each pressure reducing valve. Appropriate flow loading conditions can be set to avoid noise. The steam pressure reducing valve must be installed horizontally. For pressure reducing valve groups used in parallel, it is necessary to select different diameters and correctly set different rear valve pressures, so that the two pressure reducing valves can be put into operation successively according to the flow rate from small to large (from normal to peak).

Fushan Valve (Suzhou) Co., Ltd. was first established in, and due to development needs, an independent legal entity was established: Fushan Valve (Jiangsu) Co., Ltd., with two holding factories in Suzhou and Kunshan. The company is committed to manufacturing high-quality Fushan brand valves in the fields of air conditioning water system, process cooling water (PCW system), compressed air (CDA system), pure water system, electric butterfly valve, electric ball valve, and steam pressure reducing valve, It has a large number of loyal customers including CSCEC, CEC, CEC, and the Institute of Physics of the Chinese Academy of Sciences.